The ARPANSA calorimeter is a commercial design based on that of Domen [1]. Figure 1 shows the calorimeter in its yellow wooden support and with the vacuum system attached.

From the outside the calorimeter appears as a solid, uniform graphite cylinder. Circular graphite plates of different thicknesses can be attached to the front of the calorimeter to increase the depth of the sensitive components, and plates can be added behind to increase the overall phantom depth, if required. Internally the calorimeter is separated by small vacuum gaps into thermally isolated bodies.

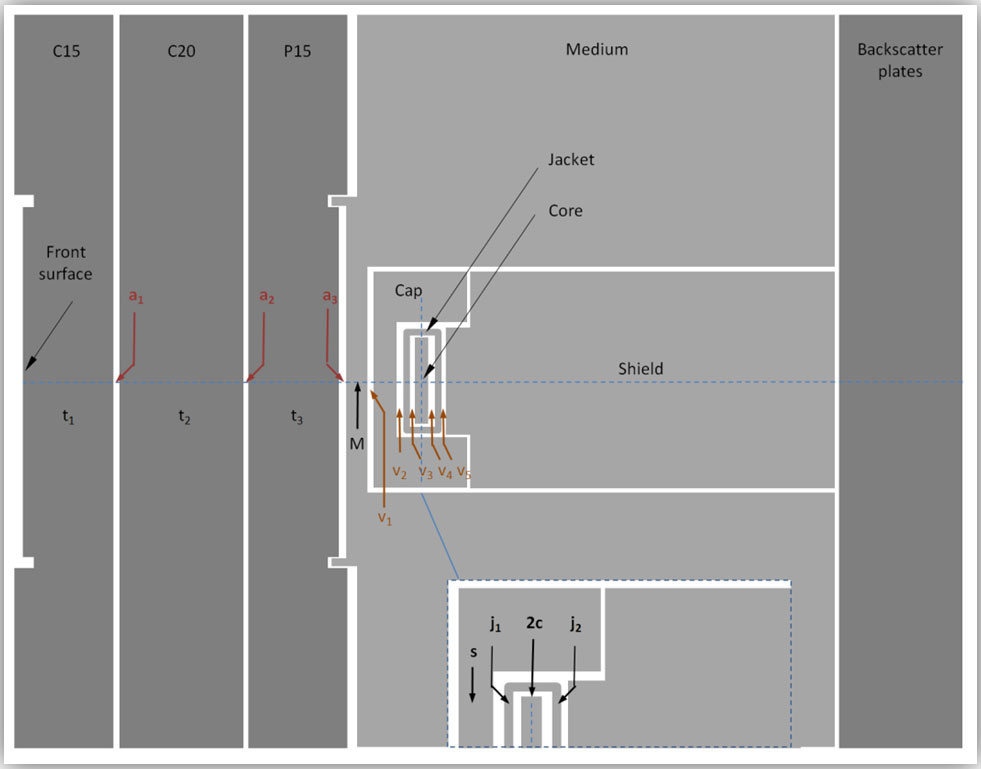

Figure 2 shows a schematic cross-section of the calorimeter. Thin vacuum gaps separate the graphite bodies and provide thermal insulation. Micro thermistors measure the temperature rise in the ‘core’ – the central graphite disk – during irradiation and when the core is heated electrically. When the radiation and electrical heating rates are matched, the rate can be found by measuring the electrical power dissipated. The mass of the core is accurately known, and the dose to graphite rate is determined by dividing the power by the mass. The dose to graphite is converted to dose to a Monte Carlo calculation.

Figure 1: The graphite calorimeter which is used at the primary standard for absorbed dose in megavoltage beams

Figure 2: Schematic diagram showing the internal structure of the calorimeter. Radiation is incident from the left. The temperature rise is measured in the 'core', a disk of graphite inside a solid graphite phantom. Very small vacuum gaps are used for thermal insulation.

References

[1]. Witzani, K E Duftschmid, Ch Strachotinsky and A Leitner, A graphite absorbed dose calorimeter in the quasi-Isothermal mode of operation, Metrologia, 20, 73-79, 1984.

[2]. The Australian Primary Standard for absorbed dose to water (graphite calorimeter), Ganesan Ramanathan, Peter Harty, Tracy Wright, Jessica Lye, Duncan Butler, David Webb and Robert Huntley, ARPANSA Technical Report Series No. 166. June 2014. Available online at: TR166.